Test methods and normative requirements for filters and filtering half masks are specified in the European Standards EN 143, EN 149 as well as the international Standard ISO 16900-3 (besides others). As a manufacturer of such testing machines we are well versed in the specifications and like to present a short overview in the following.

Masks and filters have to pass multiple tests before they can be sold. It is not only the filtration that must be verified but also, for example:

- Breathing resistance

- Ergonomics

- Mechanical strength

- Flammability

- Leackage

A lot of testing equipment is therefore needed. Lorenz Meßgerätebau has specialized in the manufacturing of machines to test the filtration efficiency and breathing resistance. These are described in more detail below.

Testing methods

The Standards define procedures for the completed product only. Masks for filters must be tested exactly as they are brought to market. Only then can they be classified according to the standardized limits. Testing the filter media alone is insufficient. This method ensures that all possible factors are considered, such as inhalation or exhalation valves or bad fitting.

Filtration efficiency

The filtration efficiency is checked with a challenge aerosol. It is directed through the filter with a predefined volumetric flow and the concentration before and after the filter is measured. The ratio of both measurements yields the filtration efficiency. All standards mentioned above require that the concentration is measured with scattering photometer. Other methods, such as particle counters, are not applicable because they cannot measure the full volumetric flow.

The aerosol itself is composed on either paraffin oil or sodium chloride particles. A generator nebulizes e.g. the paraffin oil such that particles with well-defined diameters (typically around 200 nm) are produced. Furthermore the total number of particles must be within certain limits to get reproducible results.

The scattering photometer for paraffin oil consists of a focused laser and a sensitive detector. If the light hits aerosol particles it gets scattered towards the detector. The scattering intensity is a direct measure of the aerosol concentration.

Breathing resistance

Filters and masks must not inflict a too high breathing resistance. Even wearers that perform demanding physical work must be able to breathe easily. Measuring the resistance must also be performed with the final product. A differential pressure sensor is connected to both sides of the filter to measure this property.

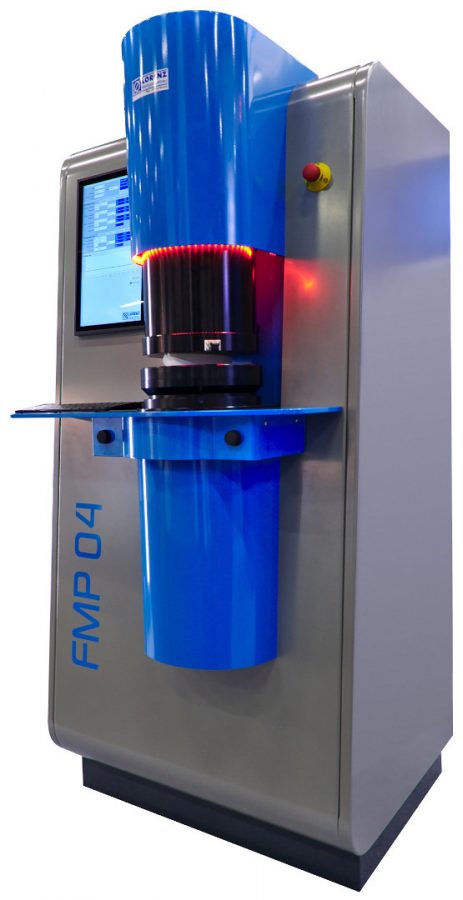

Testing machine FMP04

Our most recent testing machine, the FMP04, performs all these measurements fully automated in a single run. It contains the aerosol generator, the photometer and differential pressure sensor. Filters and masks can be mounted easily with a flexible quick-change-system. Internal pneumatic valves can switch the flow direction through the test specimen to measure in- and exhalation resistance.