Filters are available in different sizes, formats, efficiencies and target applications. As differently as filters come are the requirements towards the test equipment for them.

We have developed three different test systems that match the specific needs for testing facial masks, particulate filters as well as combined filters for particulate matter and gaseous media (NBC-systems).

ViScan

Tests for particulate air filters are defined the the standards EN 1822-1 and ISO 29463. The reference test to determine leaks is a scan-based method. But filters of classes H13 and H14 or those, which cannot be scanned, can also be tested with an oil thread test.

Our ViScan is a fully automated oil thread test system that detects leaks with a computerized camera system in very short time.

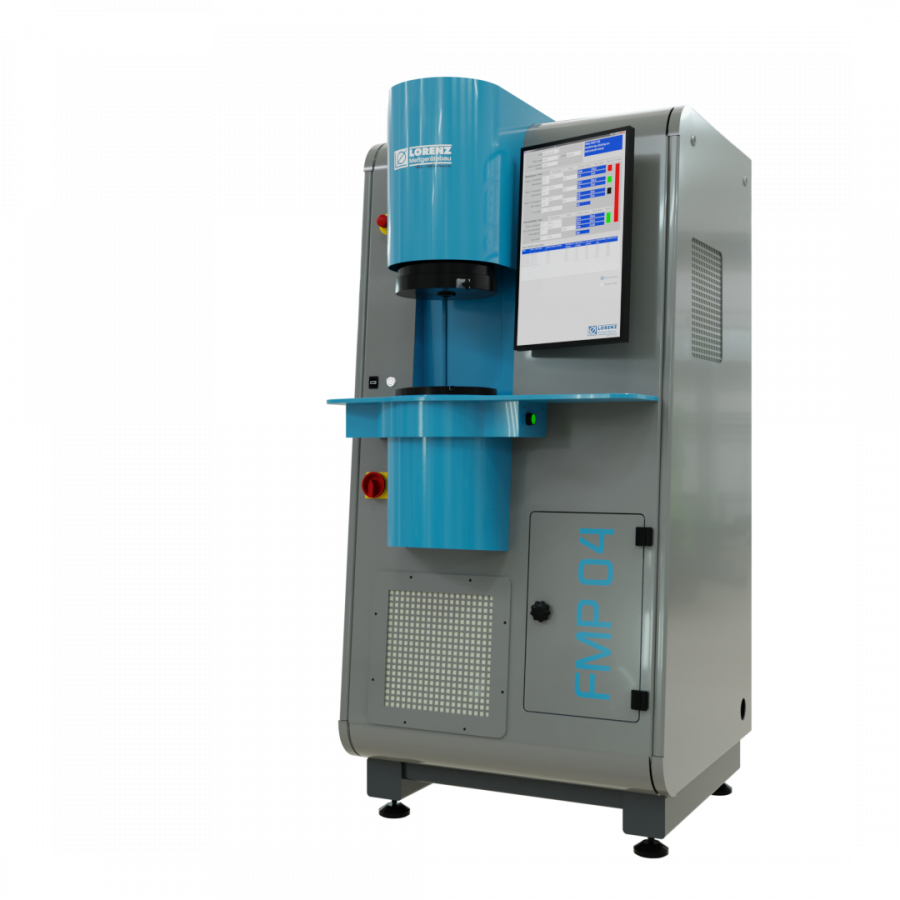

FMP04

The FMP04 is the successor of our FMP03, a test stand for respiratory protective devices and flat filter media. Besides many usability improvements the device was also extended to allow complete testing according to ISO 16900-3. Additionally, all required components, such as aerosol generator and photometer, have been integrated into this device.

FLT-3

While most systems are designed to test only the filter element itself the FLT-3 is a mobile test unit we created to check complete ventilation systems. It can test them for particulate and gaseous leaks.

NaCl testing system

Liquid filters for the food industry cannot always be tested with paraffin oil aerosols, as it is customary for facial masks or filter media. As an alternative we offer a test stand, based on our LAG generator, that produces a sodium chloride aerosol, which is completely non-toxic.

AP3E

A corner stone in aerosol technology is the optical measurement of particle concentration. An established method is light scattering, which we utilize in our laser-based light scattering photometer AP3E. It is used in many of our devices but can of course also be used standalone.